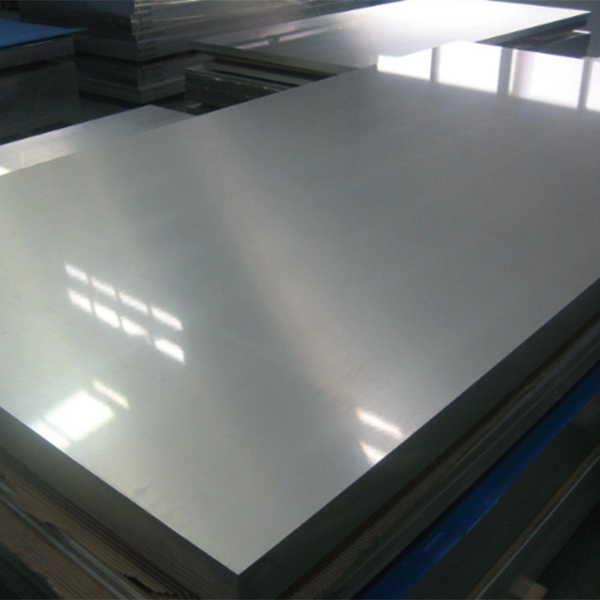

Ipuleti Lensimbi Engagqwali elenziwe ngokwezifiso elingu-304 304L

Izici ze-stainless steel plate

1. Ukushisela

Ukusetshenziswa kwemikhiqizo ehlukene kunezidingo ezihlukene zokusebenza kokushisela.Ikilasi le-tableware ngokuvamile alidingi ukusebenza kokushisela, futhi lihlanganisa ngisho namabhizinisi athile ebhodwe.Kodwa-ke, imikhiqizo eminingi idinga ukusebenza kahle kwe-welding yezinto zokusetshenziswa, njenge-tableware yesigaba sesibili, izinkomishi ze-thermos, amapayipi ensimbi, izifudumezi zamanzi, izihlinzeki zamanzi, njll.

2. Ukumelana nokugqwala

Imikhiqizo eminingi yensimbi engagqwali idinga ukumelana nokugqwala okuhle, njenge-tableware ye-Class I no-II, izitsha zasekhishini, izifudumezi zamanzi, iziphakeli zamanzi, njll. Abanye abathengisi bakwamanye amazwe nabo benza izivivinyo zokumelana nokugqwala emikhiqizweni: sebenzisa isixazululo samanzi se-NACL ukuze siyishise ukuze ibilise, bese uwuthela ngemva kwesikhathi esithile.Khipha ikhambi, geza futhi usomise, bese ukala ukwehla kwesisindo ukuze unqume izinga lokugqwala (Qaphela: Uma umkhiqizo upholishwa, okuqukethwe kwe-Fe endwangwini ebrasive noma ku-sandpaper kuzobangela ukugqwala kwendawo ngesikhathi sokuhlolwa).

3. Ukusebenza kokupholisha

Emphakathini wanamuhla, imikhiqizo yensimbi engagqwali ngokuvamile iyapholishwa ngesikhathi sokukhiqiza, futhi imikhiqizo embalwa kuphela efana nezifudumezi zamanzi kanye ne-liner yokukhipha amanzi ayidingi ukupholishwa.Ngakho-ke, lokhu kudinga ukuthi ukusebenza kokupholisha kwempahla eluhlaza kuhle kakhulu.Izici eziyinhloko ezithinta ukusebenza kokupholisha yilezi ezilandelayo:

(1) ukukhubazeka kwangaphandle kwezinto zokusetshenziswa.Okufana nokuklwebheka, ukugoba, ukukha, njll.

(2)Inkinga yezinto zokusetshenziswa.Uma ubulukhuni buphansi kakhulu, ngeke kube lula ukupholishwa lapho upholisha (impahla ye-BQ ayilungile), futhi uma ubulukhuni buphansi kakhulu, i-orange peel phenomenon ibonakala kalula ebusweni ngesikhathi sokudweba okujulile, ngaleyo ndlela ithinta impahla ye-BQ.Izakhiwo ze-BQ ezinobunzima obuphezulu zinhle uma kuqhathaniswa.

(3) Ngomkhiqizo odonswe ngokujulile, amachashazi amancane amnyama kanye ne-RIDGING izovela ebusweni bendawo ngenani elikhulu lokuguqulwa, ngaleyo ndlela kuthinte ukusebenza kwe-BQ.

4. Ukumelana nokushisa

Ukumelana nokushisa kusho ukuthi insimbi engagqwali isengakwazi ukugcina izakhiwo zayo ezinhle kakhulu zomzimba nezomshini emazingeni okushisa aphezulu.

Umthelela wekhabhoni: Ikhabhoni yakheka ngokuqinile futhi izinzile kuzinsimbi ezingenasici ze-austenitic.Izinto ezinquma i-austenite futhi zinwebe isifunda se-austenite.Ikhono lekhabhoni ukwenza i-austenite liphindwe izikhathi ezingu-30 kune-nickel, futhi ikhabhoni iyingxenye ye-interstitial engakhuphula kakhulu amandla ensimbi engagqwali ye-austenitic ngokuqiniswa kwesisombululo esiqinile.Ikhabhoni ingaphinde ithuthukise ukumelana nokugqwala kwengcindezi kwensimbi engagqwali ye-austenitic ku-chloride egxile kakhulu (njengesixazululo esibilayo esingu-42% MgCl2).

Kodwa-ke, ensimbi engagqwali ye-austenitic, ikhabhoni ivame ukuthathwa njengento eyingozi, ikakhulukazi ngenxa yokuthi ngaphansi kwezimo ezithile (njengokushisela noma ukushisisa ngo-450 ~ 850 ° C) ekumelaneni nokugqwala kwensimbi engagqwali, ikhabhoni ingasebenzisana nekhabhoni insimbi.I-Chromium yenza izinhlanganisela zekhabhoni ze-Cr23C6-high-chromium, okuholela ekuncipheni kwe-chromium yendawo, enciphisa ukumelana nokugqwala kwensimbi, ikakhulukazi ukumelana nokugqwala kwe-intergranular.ngakho-ke.Iningi lezinsimbi ezingenasici ze-chromium-nickel austenitic ezisanda kwakhiwa kusukela ngeminyaka yawo-1960 ziyizinhlobo zekhabhoni ephansi kakhulu enokuqukethwe kwekhabhoni engaphansi kuka-0.03% noma u-0.02%.Kungaziwa ukuthi njengoba okuqukethwe kwekhabhoni kuncipha, ukugqwala kwe-intergranular kwensimbi kuyehla.Uma okuqukethwe kwekhabhoni kungaphansi kuka-0.02% kuba nomthelela osobala kakhulu, futhi okunye ukuhlola kuphinde kwaveza ukuthi ikhabhoni ibuye inyuse ukugqwala kwe-pitting yensimbi engagqwali ye-chromium austenitic.Ngenxa yomphumela olimazayo wekhabhoni, hhayi kuphela okuqukethwe kwekhabhoni okufanele kulawulwe kuphansi ngangokunokwenzeka enqubweni yokuncibilikisa insimbi engagqwali ye-austenitic, kodwa nasenqubweni eyalandela yokushisa, ukusebenza okubandayo kanye nokwelashwa kokushisa ukuze kuvinjelwe ukwanda kwekhabhoni ingaphezulu lensimbi engagqwali futhi ugweme i-chromium carbides Precipitate.

5. Ukumelana nokugqwala

Uma inani lama-athomu e-chromium ensimbi lingekho ngaphansi kuka-12.5%, amandla e-electrode ensimbi angashintshwa kungazelelwe asuke ekubeni namandla angemahle aye emandleni e-electrode aqondile.Vimbela ukugqwala kwe-electrochemical.

Izinga lokukhishwa kwepuleti lensimbi engagqwali

Ipuleti lensimbi engenasici linendawo ebushelelezi, ipulasitiki ephezulu, ukuqina namandla emishini, futhi imelana nokugqwala ngama-acids, amagesi e-alkaline, izixazululo neminye imidiya.Yinsimbi engagqwali kalula, kodwa engagqwali nhlobo.Ipuleti lensimbi engagqwali lisho ipuleti lensimbi elimelana nokugqwala ngenxa yemithombo yezindaba ebuthaka efana ne-atmosphere, isitimu namanzi, kuyilapho ipuleti lensimbi elimelana ne-asidi lisho ipuleti lensimbi elimelana nokugqwala ngemidiya egqwala ngamakhemikhali njenge-asidi, i-alkali, nosawoti.Ipuleti lensimbi engagqwali selineminyaka engaphezu kwekhulu selokhu lavela ekuqaleni kwekhulu lama-20.

Ipuleti lensimbi engagqwali ngokuvamile igama elivamile lepuleti lensimbi engagqwali kanye nepuleti lensimbi elimelana ne-asidi.Eyethulwe ekuqaleni kwaleli khulu leminyaka, ukuthuthukiswa kwepuleti lensimbi engagqwali kuye kwabeka isisekelo esibalulekile kanye nesisekelo sobuchwepheshe sokuthuthukiswa kwezimboni zesimanje kanye nenqubekelaphambili yesayensi nezobuchwepheshe.Kunezinhlobo eziningi zamapuleti ensimbi engenasici anezakhiwo ezahlukene.Kancane kancane iye yakha izigaba eziningana ohlelweni lokuthuthukiswa.

Ngokwesakhiwo, ihlukaniswe izigaba ezine: i-austenitic stainless steel, i-martensitic stainless steel (okuhlanganisa imvula eyenza insimbi engagqwali ibe lukhuni), insimbi engagqwali ye-ferritic, ne-austenitic plus ferritic duplex stainless steel.Ukwakheka kwamakhemikhali okuyinhloko noma ezinye izici zepuleti lensimbi zihlukaniswa ngepuleti lensimbi engagqwali ye-chromium, ipuleti lensimbi ye-chromium nickel, ipuleti lensimbi ye-chromium nickel molybdenum, ipuleti lensimbi engenakhabhoni ephansi, ipuleti lensimbi engagqwali le-molybdenum, ukuhlanzeka okuphezulu kwepuleti lensimbi engagqwali. , njll.

Ngokwezici zokusebenza nokusetshenziswa kwamapuleti ensimbi, ihlukaniswe yaba amapuleti ensimbi engagqwali angamelana ne-nitric acid, amapuleti ensimbi engagqwali angamelana ne-sulfuric acid, amapuleti ensimbi engagqwali angangeni, amapuleti ensimbi engagqwali angagqwali, namandla aphezulu. amapuleti ensimbi engagqwali.Ngokwezici zokusebenza zepuleti lensimbi, lihlukaniswe izinga lokushisa eliphansi lepuleti lensimbi engenasici, ipuleti lensimbi engenazibuthe elingenazibuthe, ipuleti lensimbi elingenasici elisika mahhala, ipuleti lensimbi engagqwali eyi-superplastic, njll. Indlela yokuhlukanisa evame ukusetshenziswa ukuhlukanisa ngokuvumelana kuzici zesakhiwo sepuleti lensimbi, izici zokwakheka kwamakhemikhali zepuleti lensimbi kanye nenhlanganisela yakho kokubili.

Ngokuvamile ihlukaniswa ngensimbi engagqwali ye-martensitic, i-ferritic stainless steel, i-austenitic stainless steel, i-duplex stainless steel kanye nemvula eqinisa insimbi engagqwali, njll. noma ihlukaniswe izigaba ezimbili: i-chromium stainless steel ne-nickel stainless steel.Ukusetshenziswa okubanzi Okusetshenziswayo Okujwayelekile: izishintshi zokushisa ze-pulp nephepha, okokusebenza kwemishini, okokusebenza kokudaya, okokusebenza kwefilimu, amapayipi, izinto zangaphandle zezakhiwo ezisezindaweni ezisogwini, njll.

Ipuleti lensimbi engenasici linendawo ebushelelezi, ipulasitiki ephezulu, ukuqina namandla emishini, futhi imelana nokugqwala ngama-acids, amagesi e-alkaline, izixazululo neminye imidiya.Yinsimbi engagqwali kalula, kodwa engagqwali nhlobo.

Ukujiya konyawo nokujiya okujwayelekile kwepuleti lensimbi engagqwali

Ukujiya kwezinyawo kusho ukuthi ukujiya kwangempela akwehlukile kakhulu kugqinsi lwethiyori (okubizwa nangokuthi ukushuba kwelebula), okuwumehluko omncane ongemuhle.Uma ukujiya kwelebula kungu-1.0MM, ubukhulu bonyawo obudingekayo okungenani bucishe bube ngu-0.98MM-1.0MM, futhi ukujiya konyawo kungaba Kuqondwa ngokuthi "ukujiya ngokwanele", futhi ukujiya okujwayelekile ukujiya kwethiyori.Amakhoyili omshini wensimbi abhalwe uma ephuma efektri, okubonisa ukujiya kwethiyori.Lokhu ukujiya okujwayelekile.