I-Titanium alloy TA1 tube ingasetshenziswa i

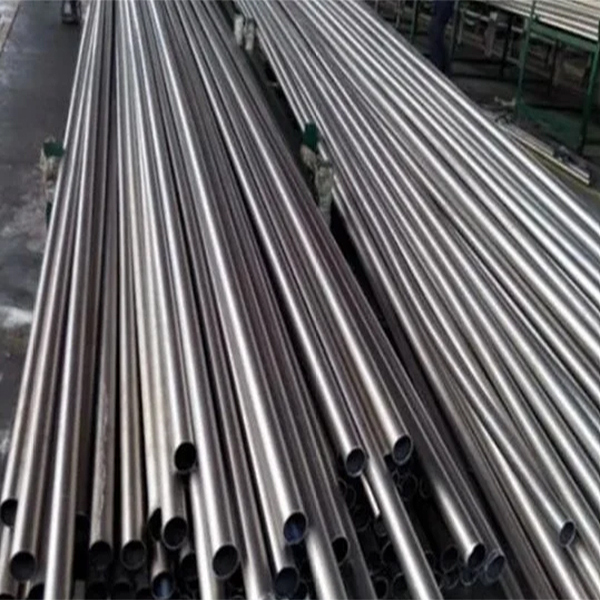

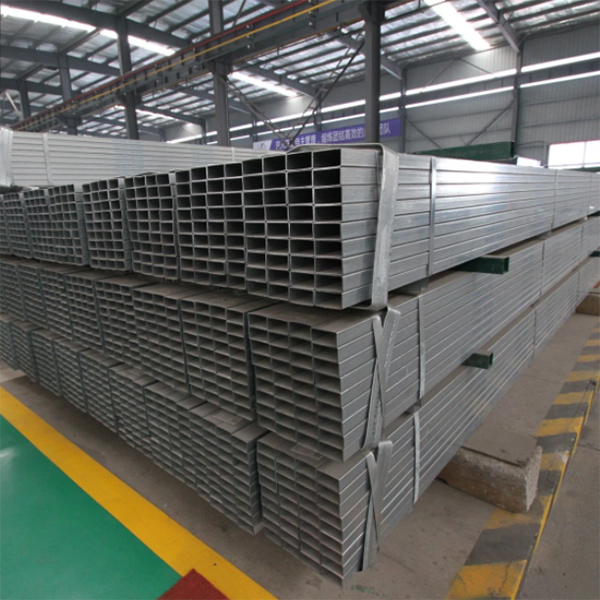

I-Titanium Alloy TA1 Tube, Yenziwe nge-titanium alloy, engahlukaniswa ngezinhlobo ezintathu ngokuya ngesakhiwo.(I-Aluminium engu-1 nethini kwengezwa ku-titanium. I-Aluminium, i-chromium, i-molybdenum, i-vanadium nezinye izakhi ze-alloying zengezwa ku-titanium. 3 I-Titanium ene-aluminium ne-vanadium nezinye izakhi.)Zinezakhiwo eziphakeme zemishini, izici ezinhle kakhulu zokunyathela, futhi zingaba ashiselwe ngezindlela ezihlukahlukene, amandla ahlangene okushisela angafinyelela ku-90% wamandla ensimbi ye-matrix, kanye nokusebenza kahle.I-Titanium tube inokumelana nokugqwala okuphezulu ku-chloride, i-sulfide ne-ammonia.Ukumelana nokugqwala kwe-titanium emanzini olwandle kungaphezulu kwalokho kwe-aluminium alloy, insimbi engagqwali ne-nickel base alloy.I-Titanium nayo inokumelana nomthelela wamanzi okuqinile.

I-Titanium Alloy TA1 Tube, Izinga Elifanele

I-GB/T 3620.1-2016 amamaki e-Titanium ne-titanium alloy kanye nokwakheka kwamakhemikhali

I-GB/T 3624-2010 Titanium ne-titanium alloy tube standard

Amashubhu e-Titanium ne-titanium alloy okushintshanisa ukushisa nama-condensers

I-TA1, i-TA2 kanye ne-TA3 yi-titanium ehlanzekile yezimboni, enezakhiwo eziphakeme zemishini, izakhiwo ezinhle kakhulu zokugxiviza, futhi zingashiselwa ngezindlela ezihlukahlukene.Amandla ahlanganisiwe ashiselwe angafinyelela ku-90% wamandla ensimbi ye-matrix, futhi ukusebenza kokusika kuhle.I-Titanium tube inokumelana nokugqwala okuphezulu ku-chloride, i-sulfide ne-ammonia.Ukumelana nokugqwala kwe-titanium emanzini olwandle kungaphezulu kwalokho kwe-aluminium alloy, insimbi engagqwali ne-nickel base alloy.I-Titanium nayo inokumelana nomthelela wamanzi okuqinile.

Isetshenziswa ekukhiqizeni amashubhu e-condenser emanzini olwandle angcolile, amanzi anokuqukethwe okuphezulu okuqinile okumisiwe, kanye namazinga aphezulu okugeleza.

I-Titanium Alloy TA1 Tube, Ukwahlukaniswa

Ngokusho kwe-histological

1. izakhi ze-aluminium nethini zengezwa ku-titanium.

2. izakhi ze-alloy ezifana ne-aluminium, i-chromium, i-molybdenum ne-vanadium yengezwa ku-titanium.

3. i-aluminium ne-vanadium yengezwa ku-titanium.

Ingxubevange ye-Titanium inamandla aphezulu kanye nokuminyana okuphansi, izakhiwo ezinhle zemishini, ukuqina okuhle nokumelana nokugqwala.Ngaphezu kwalokho: ukusebenza kwenqubo ye-titanium alloy akukuhle, ukusika okunzima.Ekucutshungulweni okushisayo, kulula kakhulu ukumunca ukungcola okufana ne-hydrogen, umoya-mpilo, i-nitrogen ne-carbon.Kukhona ukumelana nokugqoka okumpofu, inqubo yokukhiqiza eyinkimbinkimbi.

Ihlukaniswe ngezinto ezixubile

Ingxubevange esekelwe ku-titanium nezinye izakhi ezingeziwe.Ukukhiqizwa kwezimboni ze-titanium kwaqala ngo-1948. Izidingo zokuthuthukiswa kwemboni yezokundiza zenza imboni ye-titanium ithuthuke ngesilinganiso sokukhula konyaka esingaba ngu-8%.Ukukhishwa konyaka kwezinto zokucubungula ingxubevange ye-titanium sekufinyelele amathani angaphezu kuka-40,000, cishe izinhlobo ezingama-30 zengxubevange ye-titanium.Ama-titanium alloys asetshenziswa kakhulu yi-Ti-6Al-4V(TC4), Ti-5Al-2.5Sn (TA7) kanye ne-industrial pure titanium (TA1, TA2 ne-TA3).

Ngokusho kwe-utility cent

Ingxubevange ye-Titanium ingahlukaniswa ibe yingxubevange ekwazi ukumelana nokushisa, ingxubevange yamandla aphezulu, ingxubevange engagqwali (ti-molybdenum, i-ti-Palladium alloy, njll.), ingxubevange yokushisa ephansi kanye ne-alloy yokusebenza ekhethekile (i-ti-iron hydrogen storage material kanye nenkumbulo ye-ti-nickel ingxubevange), njll. Ukwakheka kanye nezakhiwo zama-alloys ajwayelekile kukhonjisiwe kuthebula.

I-Titanium Alloy TA1 Tube, Sebenzisa

I-Titanium Alloy TA1 Tube, Isetshenziselwa ikakhulukazi ukukhiqizwa kwezingxenye ze-compressor yenjini yendiza, ilandelwa amarokhethi, imicibisholo nezingxenye zesakhiwo sezindiza ezinesivinini esikhulu.Maphakathi nawo-1960, i-titanium nama-alloys ayo kwase kusetshenziswe embonini evamile ukwenza ama-electrode embonini yokuhlanza i-electrolysis, ama-condenser eziteshini zikagesi, izifudumezi zokuhluza uwoyela nokukhipha usawoti emanzini olwandle, kanye nemishini yokulawula ukungcoliswa kwemvelo.I-Titanium nama-alloys ayo isiphenduke uhlobo lwezinto zesakhiwo ezimelana nokugqwala.Ngaphezu kwalokho, iphinde isetshenziselwe ukukhiqiza izinto zokugcina i-hydrogen kanye nokubumba ama-alloys enkumbulo.

I-China yaqala ukutadisha i-titanium ne-titanium alloys ngo-1956. Maphakathi nawo-1960, impahla ye-titanium yenziwa yizimboni futhi yathuthukiswa yaba yi-TB2 alloy.

Ukwakheka Kwamakhemikhali

| Ibanga | N | C | H | Fe | THE | Al | IN | Hhayi-ke | Mo | In | Of | Amandla Okuqina (MPa) | I-Yield Strength (MPa) | Ubude(%) |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | U-Bal | 240 | 138 | amashumi amabili nane |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | U-Bal | 345 | 275 | 20 |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | U-Bal | 450 | 380 | 18 |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | 550 | 483 | 15 | |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | U-Bal | 895 | 828 | 10 |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | U-Bal | 345 | 275 | 20 |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | U-Bal | 620 | 70 | 15 |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 02-0.4 | 0.6-0.9 | U-Bal | 438 | 345 | 18 |

| Uhlobo | Singahlinzeka nge-TB3, TB6, TC4, TC6, TC11, TC17,TC18 ngokwezidingo zakho. | |||||||||||||

| Okujwayelekile | ASTM B348, ASTM F67, ASTM F136, ISO5832-2, ISO5832-3, AMS 4928, AMS 4930, ASTM F1295, ASTM F1713, MIL-T-9047 | |||||||||||||

| Isicelo | I-Metallurgy, electronics, medical, chemical, petroleum, pharmaceutical, aerospace, njll. | |||||||||||||

Isibonisi somkhiqizo