I-TC2 Titanium Alloy Aheet Plate

I-TC2 Titanium Alloy Aheet Plate,Ingxubevange esekelwe ku-titanium nezinye izakhi ezingeziwe.Kunezinhlobo ezimbili zamakristalu e-homogenous ku-titanium: i-α titanium enesakhiwo esiminyene esiyi-hexagonal ingaphansi kuka-882 ℃, futhi i-β titanium enekhiyubhu emaphakathi yomzimba ingaphezu kuka-882℃.

Izidingo zobuchwepheshe:

1. Ukwakheka kwamakhemikhali kwe-titanium ne-titanium alloy plate kuzothobelana nezinhlinzeko ze-GB/T 3620.

2. Endabeni yokuhlolwa kabusha, ukuchezuka okuvunyelwe kokwakheka kwamakhemikhali kuzothobelana nezinhlinzeko ze-GB/T 3620.

a.ukuchezuka okuvumelekile kobukhulu bepuleti kufanele kuhambisane nezinhlinzeko zeThebula 1.

b.ukuchezuka okuvunyelwe kobubanzi nobude bepuleti kufanele kuhambisane nezinhlinzeko zeThebula lesi-2.

c.amakhona epuleti kufanele asikwe abe ngama-engeli angakwesokudla ngangokunokwenzeka.Ukuchezuka akufanele kudlule ubude nobubanzi beshidi

I-TC2 Titanium Alloy Aheet Plate, Ukucaciswa Kokukhiqiza

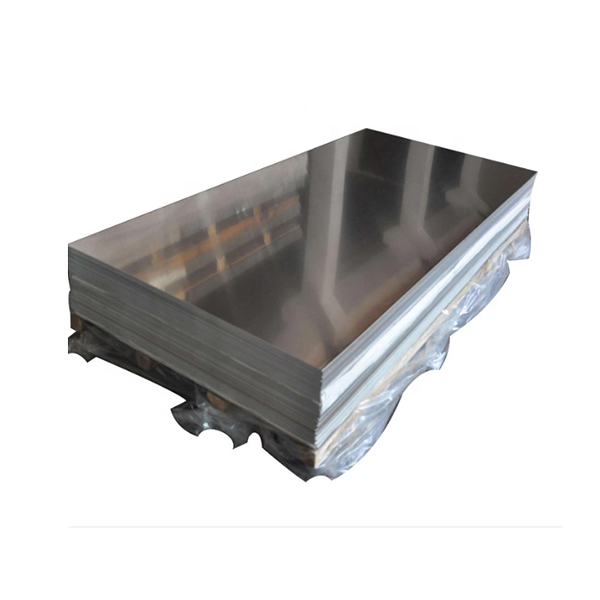

T 0.5-1.0mm × W1000mm × L 2000-3500mm

T 1.0-5.0mm × W1000-1500mm × L 2000-3500mm

T 5.0- 30mm × W1000-2500mm × L 3000-6000mm

T 30- 80mm × W1000mm × L 2000mm

I-TC2 Titanium Alloy Aheet Plate, Isimo Sokukhiqiza

Isimo sokusebenza esishisayo (R) Isimo sokusebenza esibandayo (Y) Isimo se-Annealing (M)

I-TC2 Titanium Alloy Aheet Plate, Reference Standard

1: Indlela yokuhlola ye-GB 228 Metal tensile

2: GB/T 3620.1 Titanium kanye ne-titanium alloy amamaki kanye nokwakheka kwamakhemikhali

3: GB/T3620.2 Imikhiqizo ecutshunguliwe ye-titanium ne-titanium alloy ukwakheka kwamakhemikhali nokuphambuka okuvumelekile

4: Indlela ye-GB 4698 yolwandle yokuhlaziya amakhemikhali e-titanium, i-titanium ne-ferroalloys

I-TC2 Titanium Alloy Aheet Plate, Izidingo Zobuchwepheshe

1: Ukwakheka kwamakhemikhali kwe-titanium ne-titanium alloy plate kuzothobelana nezinhlinzeko ze-GB/T 3620.1.Endabeni yokuhlolwa kabusha, ukuchezuka okuvunyelwe kokwakheka kwamakhemikhali kuzothobelana nezinhlinzeko ze-GB/T 3620.2.

2: Ukuchezuka okuvumelekile kobukhulu bepuleti kufanele kuhambisane nezinhlinzeko zeThebula 1.

3: Ukuchezuka okuvunyelwe kobubanzi nobude bepuleti kufanele kuthobelane nezinhlinzeko zeThebula 2.

4: Amakhona epuleti kufanele asikwe abe ama-engeli angakwesokudla ngangokunokwenzeka.Ukuchezuka akufanele kudlule ubude nobubanzi beshidi

Ingxubevange

I-TC2 Titanium Alloy Aheet Plate,Ingxubevange esekelwe ku-titanium nezinye izakhi ezingeziwe.Kunezinhlobo ezimbili zamakristalu e-homogenous ku-titanium: i-α titanium enesakhiwo esiminyene esiyi-hexagonal ingaphansi kuka-882 ℃, futhi i-β titanium enekhiyubhu emaphakathi yomzimba ingaphezu kuka-882℃.

(1) Izakhi ze-alloying zingahlukaniswa ngezigaba ezintathu ngokuya ngomphumela wazo ekushiseni kwesigaba soshintsho:

Izakhi ezizinzile ze-α, njenge-aluminium, i-carbon, umoya-mpilo ne-nitrogen, zinzisa isigaba se-α futhi zandise izinga lokushisa lokushintsha kwesigaba.I-Aluminium iyisici esiyinhloko se-alloying ye-titanium alloy, enomphumela osobala ekuthuthukiseni amandla engxubevange ekamelweni lokushisa kanye nokushisa okuphezulu, ukunciphisa amandla adonsela phansi athile nokwandisa i-elastic modulus.

(2) β -izakhi ezizinzile zingahlukaniswa zibe izinhlobo ezimbili: isocrystalline ne-eutectoid.Imikhiqizo eyenziwe nge-titanium alloy

Owokuqala une-molybdenum, i-niobium, i-vanadium nokunye;Lesi sakamuva sine-chromium, manganese, ithusi, insimbi, i-silicon nokunye.

(3) Izakhi ezinomphumela omncane kuzinga lokushisa lokushintsha kwesigaba ziyizakhi ezingathathi hlangothi, njenge-zirconium ne-tin.

I-oksijeni, i-nitrogen, i-carbon ne-hydrogen ukungcola okuyinhloko kuma-alloys e-titanium.Ukuncibilika kwe-oksijeni ne-nitrogen esigabeni se-α kukhulu, okunomthelela omkhulu wokuqinisa ingxube ye-titanium, kodwa kunciphisa ipulasitiki.Okuqukethwe komoyampilo ne-nitrogen ku-titanium kuvamise ukuba ngaphansi kuka-0.15 ~ 0.2% no-0.04 ~ 0.05%, ngokulandelana.I-Hydrogen inokuncibilika okuncane kakhulu esigabeni sika-α, futhi i-hydrogen eningi kakhulu encibilikiswe ku-titanium alloys ikhiqiza ama-hydrides, enza ingxubevange ibe brittle.Okuqukethwe kwe-hydrogen ku-titanium alloy kuvame ukulawulwa ngaphansi kuka-0.015%.Ukuncibilika kwe-hydrogen ku-titanium kuyabuyiseleka emuva futhi kungasuswa nge-vacuum annealing.

Ukwakheka Kwamakhemikhali

| Ibanga | N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | U-Bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | U-Bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | U-Bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | U-Bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | U-Bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | U-Bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | U-Bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 0.2-0.4 | 0.6-0.9 | U-Bal |

Amandla Okuqina

| Ibanga | Ubude(%) | Amandla Okuqina (Amaminithi) | Amandla Okukhiqiza (Okuncane) | ||

| ksi | Mpa | ksi | Mpa | ||

| Gr1 | 24 | 35 | 240 | 20 | 138 |

| Gr2 | 20 | 50 | 345 | 40 | 275 |

| Gr3 | 18 | 65 | 450 | 55 | 380 |

| Gr4 | 15 | 80 | 550 | 70 | 483 |

| Gr5 | 10 | 130 | 895 | 120 | 828 |

| Gr7 | 20 | 50 | 345 | 40 | 275 |

| Gr9 | 15 | 90 | 620 | 70 | 438 |

| Gr12 | 18 | 70 | 438 | 50 | 345 |

Imikhiqizo ye-Titanium kanye ne-alloy

| Igama lomkhiqizo | Imininingwane |

| I-Titanium Rod & Bar & Ingots | Ф3mm~Ф1020mm, isisindo esiphezulu sifika ku-12t |

| I-Titanium Slab | (80~400)mm×(~1500)mm×(~2600)mm |

| I-Titanium Forgings | Isisindo ngocezu≤2000kg |

| Amapuleti e-Titanium Hot-rolled | (4~100)mm×(800~2600)mm×(2000~12000)mm |

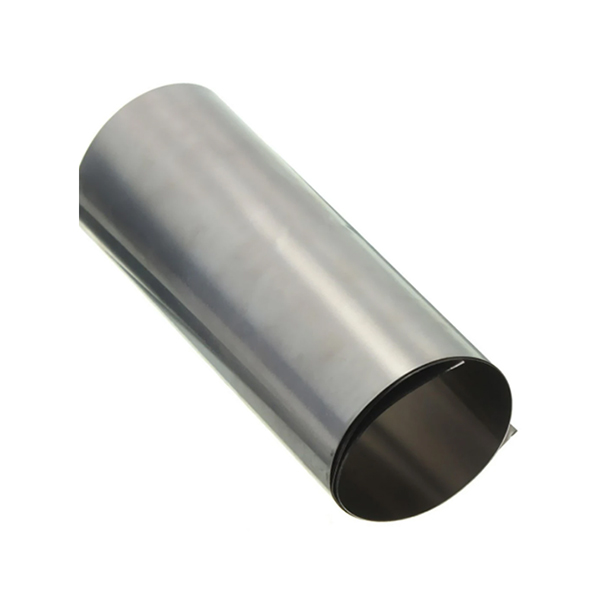

| Ishidi Eligoqelwe Ngokubandayo le-Titanium | (0.01~4.0)mm×(800~1560)mm×( ~6000) mm |

| I-Titanium Foil / Imichilo | (0.01~2.0)mm×(800~1560)mm×L |

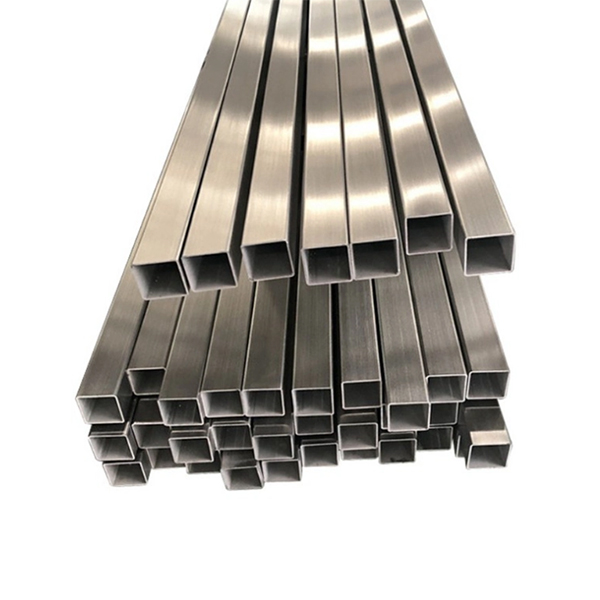

| Amashubhu e-Titanium / Amapayipi | Ф(3~114)mm×( 0.2~5)mm × (~15000)mm |

| Amazinga | I-GB,GJB,ASTM,AMS,BS,DIN,DMS,JIS,ГОСт |

| Ibanga le-Titanium |

|

Isibonisi somkhiqizo