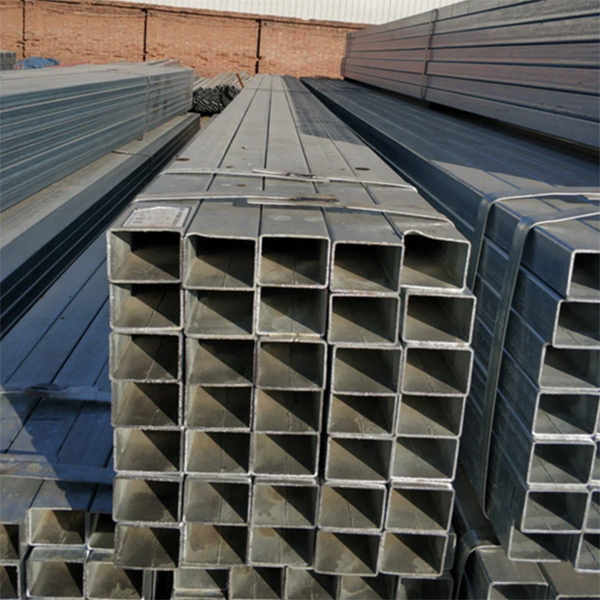

I-Square Structural Steel Tubing

Ishubhu yensimbi yesakhiwo esiyisikwele, eyaziwa nangokuthi ipayipi elishiselwe, yenziwe ngepuleti lensimbi noma umucu ngemva kokugoqa okwenza ipayipi eliyisikwele elishiselwe.

Amashubhu ensimbi yesakhiwo esikwele, Izinto ezisetshenziswa kakhulu yilezi: Q235A, Q235C, Q235B, 16Mn, 20#, Q345, L245, L290, X42, X46, X60, X80, 0Cr13, 1Cr17, 01Ni10Cr8 ku-19Cr19, 1Ni10Cr1, 1Ni10Cr19

Ipayipi elishiselwe insimbi engagqwali yokuhlobisa (i-GB/T 18705-2002), ipayipi lensimbi engagqwali elishiselwe ukuhlobisa isakhiwo (JG/T 3030-1995), ipayipi lensimbi elishiselwe ukuthutha uketshezi olunomfutho ophansi (GB/T 3091-2001), kanye ipayipi elishiselwe insimbi yomshini wokushisa (YB4103-2000).

Inqubo Yokukhiqiza

Amashubhu ensimbi ayisikwele, izikhala ezincane zingasetshenziswa ukukhiqiza amapayipi ashiselwe anobubanzi obukhudlwana, futhi izikhala ezinobubanzi obufanayo zingasetshenziswa ukukhiqiza amapayipi ashiselwe anobubanzi obuhlukene.Kodwa uma kuqhathaniswa nobude obufanayo bepayipi lesikwele lomthungo oqondile, ubude be-weld bukhuphuka ngo-30 ~ 100%, futhi isivinini sokukhiqiza siphansi.

Ipayipi elikhulu noma eliwugqinsi ngobubanzi obuyisikwele besakhiwo sensimbi, Ngokuvamile lenziwe nge-billet yensimbi ngokuqondile, kanye nepayipi elincane elishiselwe odongeni elincanyana elishiselwe ipayipi elishiselwe kuphela lidinga ukushiselwa ngokuqondile ngebhande lensimbi.Ngemva kokupholisha okulula, ucingo selulungile.Ngakho-ke, ipayipi elincane elishiselwe ubukhulu lisebenzisa i-seam welding eqondile, ipayipi elikhulu elishiselwe ubukhulu lisebenzisa i-spiral welding.

Shape Ukusebenza

amashubhu ensimbi ayisikwele, Yigama lepayipi eliyisikwele, okuyipayipi elinobude obufanayo nhlangothi zombili.Yenziwe nge-strip steel ngokusebenzisa isixazululo senqubo nokugoqa.Imvamisa, umugqa awupakishiwe, uyisicaba, ugoqekile, ushiselwe ube yishubhu eliyindilinga, bese ugoqwa ngeshubhu eliyindilinga Q215 elishiselwe ishubhu lesikwele bese lisikwa libe ngobude besidingo.Inombolo evamile ngu-50 iphakethe ngalinye.Amandla abhekisela emsebenzini wokumelana nokulimala (ukuguqulwa kwepulasitiki okufanele noma ukuphuka) kwedatha yepayipi yesikwele esishiselwe i-Q215 ngaphansi komthwalo omile.Ngoba umthwalo wefomu lokushuba, ukufinyela, ukujikajika, ukugunda nezinye izindlela, ngoba amandla nawo ahlukaniswe amandla aqinile, amandla okucindezela, amandla okugoba, amandla okugunda nokunye.Zonke izinhlobo zamandla zivame ukuba nokuxhumana okuqondile, ukusetshenziswa okuvamile kwamandla aqinile njengenaliti yamandla eyisisekelo.Amandla okumelana nokubhujiswa abizwa ngokuthi ukuqina kwe-charge.

Umthwalo wezingxenye ezinenqubekelaphambili enkulu ubizwa ngokuthi i-charge array load.Amandla, ipulasitiki kanye ne-Engeli okuxoxwe ngayo ngemuva kokuqina kweshaja yepayipi eliyisikwele ngaphansi kwesenzo sohlu lwezinhlamvu zensimbi zonke zingamageji okusebenza komshini ngaphansi komthwalo omile wepayipi eliyisikwele le-Q215 elishiselwe.Empeleni, imishini eminingi ingaphansi komthwalo ophindaphindiwe wokuqashwa, ngaphansi kwalesi simo lonke ithuba lokukhathala.I-Angle yokukhathala ukukala idatha yensimbi ileveli ethambile neqinile yenaliti.Indlela engavamile kakhulu yokulungiswa kwe-Angle yangaphakathi empilweni yamanje ingcindezi ye-Angle method, okuwukusebenzisa inombolo ethile yalokho ukuma kwekhanda lokucindezela ngaphansi komthwalo othile kucindezelwa endaweni ehloliwe ye-Q215 ye-square tube data surface, ngokusho. kungcindezi yezinga lokunquma inani le-engeli.Izindlela ezimbalwa ezisetshenzisiwe yi-HB, HRA, HRB, HRC ne-HV.I-plasticity ye-angular ibhekisela emandleni edatha yensimbi ngaphansi komthwalo, ukuguqulwa kwepulasitiki (ukuguqulwa okuhlala njalo) ngaphandle kokulimala.I-Plastiki Q215 eshiselwe ishubhu lesikwele esingajwayelekile ishubhu lesikwele esingenamthungo iwubunjwa obungenamthungo oyindilinga we-extrusion.Ishubhu elingenamthungo kanye namaphoyinti wokushisela asho ukuthi, luhlobo lweshubhu yekhanda lesikwele (ishubhu le-torque), umoya wezinhlobo eziningi zezinto ezikwazi ukwenza ipayipi lephathi (i-square torque tube), iphakathi ukusuka, ngani, ukusebenzisa ini iwumgogodla, idlanzana elikhulu Q215 elishiselwe ishubhu lensimbi eliyisikwele njengedlanzana, lesakhiwo seshubhu lesikwele, ishubhu lesikwele somcako omhlophe, ipayipi labakhi (ishubhu lesikwele torque), njll. Ishubhu yesikwele Isingeniso Imisebenzi yeshubhu yesikwele.

Ukwakheka Kwamakhemikhali

Impahla ye-S460N

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | I-CEV |

| ubuningi 0.2 | ubuningi 0.6 | 1 - 1.7 | ubuningi 0.8 | ubuningi 0.03 | ubuningi 0.025 | ubuningi 0.3 | ubuningi 0.1 | ubuningi 0.2 | ubuningi 0.025 | ubuningi 0.05 | ubuningi 0.05 | ubuningi 0.02 | ubuningi 0.55 | ubuningi 0.55 |

Impahla ye-S420N

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | I-CEV |

| ubuningi 0.2 | ubuningi 0.6 | 1 - 1.7 | ubuningi 0.8 | ubuningi 0.03 | ubuningi 0.025 | ubuningi 0.3 | ubuningi 0.1 | ubuningi 0.2 | ubuningi 0.025 | ubuningi 0.05 | ubuningi 0.05 | ubuningi 0.02 | ubuningi 0.55 | ubuningi 0.52 |

I-S420NL impahla:

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | I-CEV |

| ubuningi 0.2 | ubuningi 0.6 | 1 - 1.7 | ubuningi 0.8 | ubuningi 0.025 | ubuningi 0.02 | ubuningi 0.3 | ubuningi 0.1 | ubuningi 0.2 | ubuningi 0.025 | ubuningi 0.05 | ubuningi 0.05 | ubuningi 0.02 | ubuningi 0.55 | ubuningi 0.52 |

I-S460NL impahla:

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | I-CEV |

| ubuningi 0.2 | ubuningi 0.6 | 1 - 1.7 | ubuningi 0.8 | ubuningi 0.025 | ubuningi 0.02 | ubuningi 0.3 | ubuningi 0.1 | ubuningi 0.2 | ubuningi 0.025 | ubuningi 0.05 | ubuningi 0.05 | ubuningi 0.02 | ubuningi 0.55 | ubuningi 0.55 |

Izakhiwo Zemishini

Impahla ye-S460N

| Ubukhulu begama (mm): | ku-100 | 100 - 200 |

| Rm- Amandla e-Tensile (MPa) | 540-720 | 530-710 |

| Ubukhulu begama (mm): | kuye 16 | 16-40 | 40-63 | 63-80 | 80 - 100 | 100 - 150 | 150 - 200 |

| ReH- Amandla esivuno esincane (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Amandla omthelela (J) ubude., (+N) | +20° 55 | 0° 47 | -10° 43 | -20° 40 | |

| KV- Impact energy (J) transverse, (+N) | +20° 31 | 0° 27 | -10° 24 | -20° 20 | |

| Ubukhulu begama (mm): | kuye 16 | 16-40 | 40-63 | 63-80 | 80 - 200 |

| A- Min.ubude Lo = 5,65 √ Ngakho (%) | 17 | 17 | 17 | 17 | 17 |

I-S420N impahla:

| Ubukhulu begama (mm): | ku-100 | 100 - 200 | 200 - 250 |

| Rm- Amandla e-Tensile (MPa) | 520-680 | 500-650 | 500-650 |

| Ubukhulu begama (mm): | kuye 16 | 16-40 | 40-63 | 63-80 | 80 - 100 | 100 - 150 | 150 - 200 | 200 - 250 |

| ReH- Amandla esivuno esincane (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Amandla omthelela (J) ubude., (+N) | +20° 55 | 0° 47 | -10° 43 | -20° 40 | |

| KV- Impact energy (J) transverse, (+N) | +20° 31 | 0° 27 | -10° 24 | -20° 20 | |

| Ubukhulu begama (mm): | kuye 16 | 16-40 | 40-63 | 63-80 | 80 - 200 | 200 - 250 |

| A- Min.ubude Lo = 5,65 √ Ngakho (%) | 19 | 19 | 19 | 18 | 18 | 18 |

I-S420NL impahla:

| Ubukhulu begama (mm): | ku-100 | 100 - 200 | 200 - 250 |

| Rm- Amandla e-Tensile (MPa) | 520-680 | 500-650 | 500-650 |

| Ubukhulu begama (mm): | kuye 16 | 16-40 | 40-63 | 63-80 | 80 - 100 | 100 - 150 | 150 - 200 | 200 - 250 |

| ReH- Amandla esivuno esincane (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Amandla omthelela (J) ubude., (+N) | +20° 63 | 0° 55 | -10° 51 | -20° 47 | -30 ° 40 | -40 ° 31 | -50° 27 | |

| KV- Impact energy (J) transverse, (+N) | +20° 40 | 0° 34 | -10° 30 | -20° 27 | -30 ° 23 | -40 ° 20 | -50° 16 | |

| Ubukhulu begama (mm): | kuye 16 | 16-40 | 40-63 | 63-80 | 80 - 200 | 200 - 250 |

| A- Min.ubude Lo = 5,65 √ Ngakho (%) | 19 | 19 | 19 | 18 | 18 | 18 |

I-S460NL impahla:

| Ubukhulu begama (mm): | ku-100 | 100 - 200 |

| Rm- Amandla e-Tensile (MPa) | 540-720 | 530-710 |

| Ubukhulu begama (mm): | kuye 16 | 16-40 | 40-63 | 63-80 | 80 - 100 | 100 - 150 | 150 - 200 |

| ReH- Amandla esivuno esincane (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Amandla omthelela (J) ubude., (+N) | +20° 63 | 0° 55 | -10° 51 | -20° 47 | -30 ° 40 | -40 ° 31 | -50° 27 | |

| KV- Impact energy (J) transverse, (+N) | +20° 40 | 0° 34 | -10° 30 | -20° 27 | -30 ° 23 | -40 ° 20 | -50° 16 | |

| Ubukhulu begama (mm): | kuye 16 | 16-40 | 40-63 | 63-80 | 80 - 200 |

| A- Min.ubude Lo = 5,65 √ Ngakho (%) | 17 | 17 | 17 | 17 | 17 |

Isibonisi somkhiqizo