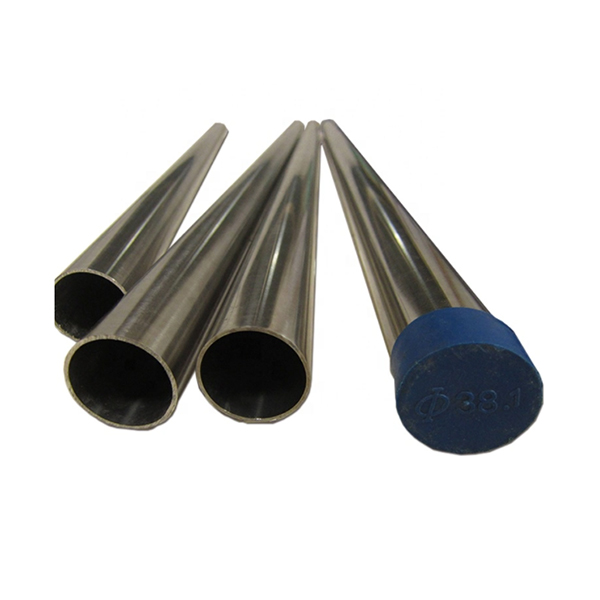

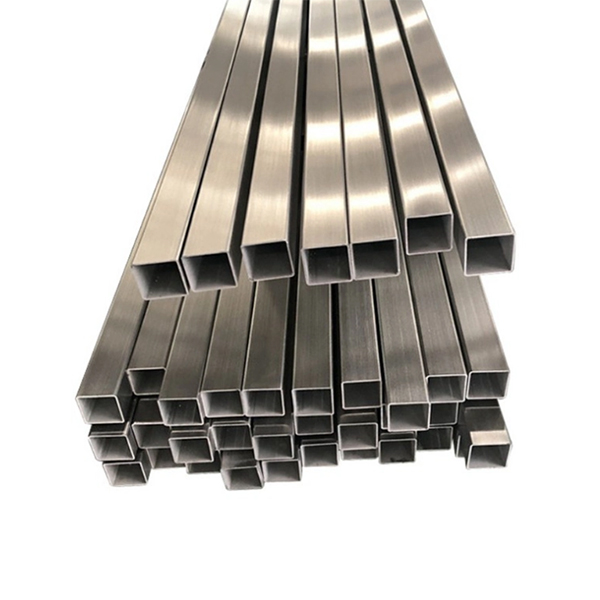

Ishubhu Lensimbi Eligoqiwe Elingenamthungo

I-Hot Rolled Seamless Steel Tube, Ukuginqika okushisayo kuhlobene nokugoqeka okubandayo, ukugoqa okubandayo kuginqika ngaphansi kwezinga lokushisa le-recrystallization, futhi ukugoqeka okushisayo kugingqika ngaphezu kwezinga lokushisa lokuvuselela kabusha.

Ishubhu Lensimbi Eligoqiwe Elingenamthungo Elishisayo, Izinzuzo

Ingacekela phansi ukwakheka kwensimbi yensimbi, icwenge usayizi wokusanhlamvu wensimbi, futhi isuse amaphutha e-microstructure, ukuze isakhiwo sensimbi sihlanganiswe futhi izakhiwo zemishini zithuthukiswe.Lokhu kuthuthukiswa kubonakala ngokuyinhloko ekugibeleni, ukuze insimbi ingabi yi-isotropic ngezinga elithile.Amabhamuza, imifantu kanye nokuxega okwakhiwa ngesikhathi sokubunjwa kungashiselwa ngaphansi kwezinga lokushisa eliphezulu nokucindezela.

Ukwahlukanisa

I-Hot Rolled Seamless Steel Tube, Ihlukaniswe ngepayipi lensimbi elijwayelekile, ipayipi lensimbi elicindezelayo eliphansi neliphakathi, ipayipi lensimbi elicindezelwe kakhulu, ipayipi lensimbi yealloy, ipayipi lensimbi engagqwali, ipayipi lokuqhekeka kwe-petroleum, ipayipi lensimbi ye-geological kanye nelinye ipayipi lensimbi.

Ipayipi lensimbi elibandayo eligoqiwe (dayela) elingenamthungo ngaphezu kwepayipi lensimbi elijwayelekile, ipayipi lensimbi elinomfutho ophansi naphakathi, ipayipi lensimbi elinomfutho ophakeme, ipayipi lensimbi yengxubevange, ipayipi lensimbi engagqwali, ipayipi lokuqhekeka likaphethiloli, elinye ipayipi lensimbi, kuhlanganisa ne-carbon thin- ipayipi lensimbi elinezindonga, ipayipi lensimbi elixutshwe nensimbi, ipayipi lensimbi engagqwali, ipayipi lensimbi elimise okukhethekile.Ububanzi bangaphandle bepayipi eligoqiwe elingenamthungo ngokuvamile likhulu kuno-32mm futhi ukujiya kodonga kungu-2.5-75mm.Ububanzi obungaphandle bepayipi lensimbi eligoqiwe elibandayo lingafinyelela ku-6mm futhi ukushuba kodonga kungafinyelela ku-0.25mm.Ububanzi bangaphandle bepayipi elinezindonga ezincane bungafinyelela ku-5mm futhi ukujiya kodonga kungaphansi kuka-0.25mm.

Ipayipi lensimbi elingenamthungo elijwayelekile: lenziwe ngensimbi eyi-10, 20, 30, 35, 45 kanye nezinye izinga okusezingeni eliphezulu carbon bonded steel 16Mn, 5MnV kanye nezinye low ingxubevange insimbi yesakhiwo noma 40Cr, 30CrMnSi, 45Mn2, 40MnB kanye nezinye ingxubevange yensimbi hot ingxubevange abandayo rolling.10, 20 kanye nezinye ipayipi elingenamthungo elikhiqiza i-carbon steel eliphansi lisetshenziselwa ikakhulukazi ipayipi loketshezi.I-45, 40Cr kanye nenye insimbi ye-carbon ephakathi eyenziwe ngepayipi elingenamthungo ukwenza izingxenye zemishini, njengezimoto, izingxenye ezigcizelelwe ngogandaganda.Ukusetshenziswa okuvamile kwepayipi lensimbi engenamthungo ukuze kuqinisekiswe amandla kanye nokuhlolwa okuphansi.Amapayipi ensimbi agoqwe ashisayo ahanjiswa esimweni esishisayo esigoqiwe noma esiphathwa ngokushisa.Ukulethwa okugoqiwe okubandayo kuyaphathwa ukushisa.

Ukuchezuka okuvunyelwe kobubanzi obujwayelekile obungaphandle

I-D1 ±1.5%, ubuncane ± 0.75mm

D2 plus noma susa 1.0%.Okungenani +/ - 0.50 mm

I-D3 + / - 0.75%.Okungenani +/ - 0.30 mm

I-D4 + / - 0.50%.Okungenani +/ - 0.10 mm

Ifomula yokubala isisindo seshubhu lensimbi

[(i-diameter yangaphandle - ukujiya kodonga)* ukujiya kodonga]x0.02466=kg/ m (isisindo imitha)

Ishubhu Lensimbi Eligoqiwe Elingenamthungo Elishisayo, Izinjongo Ezisebenzayo

1. Isigaba sokwakha sithi: ngaphansi kwepayipi ukuthutha kungaphezulu, ukukhishwa kwesakhiwo samanzi angaphansi komhlaba, ukuthuthwa kwamanzi ashisayo ku-boiler.

2. Ukucubungula imishini, umkhono wokuthwala, ukucubungula izesekeli zemishini, njll.

3. Ugesi: ukudluliswa kwegesi, ipayipi loketshezi lokuphehla amandla amanzi.

4. Ipayipi ye-antistatic yesitshalo samandla omoya, njll.

Ukucaciswa

| Igama lomkhiqizo | Ipayipi/ishubhu yensimbi engagqwali |

| Okujwayelekile | ASME, ASTM, EN,BS,GB,DIN,JIS njll |

| Ibhrendi | 201/202/304/304L/316/316L/ 321/309S/310S/410/420/430 |

| Isitifiketi | BV, ISO, CE, SGS njll |

| Uhlobo | Ayinamthungo futhi ishiselwe |

| I-Outer Diameter (OD) | 3-1220mm |

| Ubukhulu | 0.5-50mm |

| Ubude | 6000mm 5800mm 12000mm noma ngokwezifiso |

| Icebo | Idwetshiwe Okubandayo noma Okushisayo |

| Ubuso | 2B, No.1, No.4, HL, BA, 8K njll |

| Isicelo | Imboni, amakhemikhali, ugesi, imishini, izakhiwo, umhlobiso, njll. |

| Ukupakisha | Ukupakisha okujwayelekile okuthekelisa okufanele ulwandle |

| Isikhathi sokuthumela | 7-15 Izinsuku Zokusebenza Ngemva Kwediphozithi |

| TradeTerms | FOB, CFR, CIF, EXW |

| Imigomo Yokukhokha | 30%T/T,L/C |

Ukwelashwa Okungaphezulu

| Ubuso | Incazelo | Isicelo |

| No.1 | Ingaphezulu liqedwa ngokwelashwa kokushisa kanye nokukhetha noma izinqubo ezihambisana lapho ngemva kokuginqika okushisayo. | Ithangi lamakhemikhali, ipayipi njll. |

| No.3 | Lawo aqedelwa ngokupholishwa ngama-abrasives No.100 kuya ku-No.120 acaciswe ku-JIS R6001. | Izitsha zasekhishini, ukwakhiwa kwebhilidi njll. |

| No.4 | Lawo aqedelwa ngokupholishwa ngama-abrasives No.150 kuya ku-No.180 acaciswe ku-JIS R6001. | Izitsha zasekhishini, Ukwakhiwa kwebhilidi, Imishini yezokwelapha njll. |

| 2B | Lezo ziqedwa, ngemva kokuginqika okubandayo, ngokuphathwa ukushisa, ukucotshwa noma okunye ukwelashwa okufanayo futhi ekugcineni ngokuginqika okubandayo ukuze kunikezwe ukukhanya okufanele. | Imishini yezokwelapha, Imboni Yokudla, Izinto zokwakha, Izitsha zasekhishini njll. |

| I-BA (No.6) | Lezo zicutshungulwe ngokwelashwa kokushisa okukhanyayo ngemuva kokugoqa okubandayo. | Izitsha zasekhishini, Impahla kagesi, ukwakhiwa kwebhilidi njll. |

| Isibuko (No.8) | Ecwebezela njengesibuko | Ukwakhiwa kwesakhiwo, ukuhlobisa njll. |

| Izinwele | Lezo eziqediwe zokupholishwa ukuze zinikeze imivimbo yokupholisha eqhubekayo ngokusebenzisa i-abrasive yosayizi ofanele wokusanhlamvu. | Ukwakhiwa Kwezakhiwo njll. |

Ukwakheka Kwamakhemikhali

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo | |||||

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7.5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - | |||||

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - | |||||

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - | |||||

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - | |||||

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - | |||||

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - | |||||

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - | |||||

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | ||||||

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0- | |||||

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 - | |||||

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - | |||||

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - | |||||

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - | |||||

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 | |||||

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 | |||||

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | |||||

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0.22 | 0. 24 -0 .26 | - | |||||

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - | |||||

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - | |||||

| Umkhiqizo Igama | Okubalulekile | Okujwayelekile | Usayizi(mm) | Isicelo | |||||||||

| Ishubhu lokushisa eliphansi | 16MnDG 10MnDG 09DG 09Mn2VDG 06Ni3MoDG I-ASTM A333 | I-GB/T18984- 2003 I-ASTM A333 | OD: 25mm ~ 508mm WT: 3mm ~ 100mm | Faka ku - 45 ºC ~ 195 ºC umkhumbi wengcindezi yezinga lokushisa eliphansi kanye nepayipi lokushisa eliphansi lokushisa | |||||||||

| Ishubhu ye-boiler enengcindezi ephezulu | 20G I-ASTMA106B I-ASTMA210A ST45.8-III | I-GB5310-1995 I-ASTM SA106 I-ASTM SA210 I-DIN17175-79 | I-OD:8-1240* I-WT: 1-200 | Ifanele ukukhiqiza ishubhu ye-boiler enengcindezi ephezulu, unhlokweni, ipayipi lesitimu, njll | |||||||||

| I-petroleum cracking tube | 10 20 | I-GB9948-2006 | I-OD: 8-630* WT:1-60 | Isetshenziswa ku-oyela yokucwenga esithandweni somlilo, ishubhu yokushisisa ukushisa | |||||||||

| Ishubhu le-boiler enengcindezi ephansi | 10# 20# 16Mn, Q345 | I-GB3087-2008 | I-OD:8-1240* I-WT: 1-200 | Ilungele ukwakhiwa kwesakhiwo esihlukahlukene se-boiler ye-low and medium pressure boiler kanye ne-locomotive boiler | |||||||||

| Isakhiwo esijwayelekile kweshubhu | 10#,20#,45#,27SiMn I-ASTM A53A,B 16Mn, Q345 | I-GB/T8162- 2008 I-GB/T17396- 1998 I-ASTM A53 | I-OD:8-1240* I-WT: 1-200 | Faka isicelo esakhiweni esijwayelekile, ukwesekwa kobunjiniyela, ukucutshungulwa komshini, njll | |||||||||

| Isikhwama samafutha | J55,K55,N80,L80 C90,C95,P110 | I-API SPEC 5CT ISO11960 | I-OD:60-508* I-WT:4.24-16.13 | Isetshenziselwa ukukhipha uwoyela noma igesi ku-oyela Wells casing, esetshenziselwa uwoyela kanye negesi eceleni kodonga | |||||||||

Isibonisi somkhiqizo