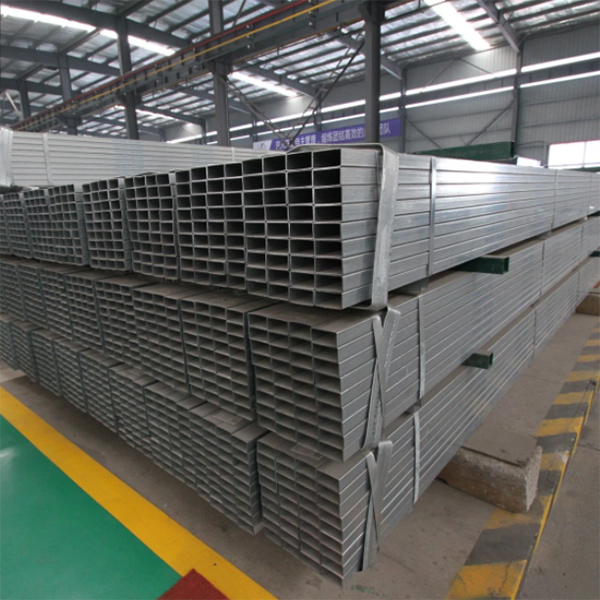

I-Carbon Steel Rectangular Tubing

Thenga e-China carbon steel Ishubhu elingunxande Siwubuchopho bakho!

Misa ukusesha kwakho manje futhi uhlale nathi, ngoba --

1. Siqinisekisa ukukunikeza amapayipi ensimbi ekhwalithi ephezulu kunamanye ngentengo efanayo.

2.Kumelwe sikubuze inani eliphansi kunabanye bekhwalithi efanayo.

3. 80% wamakhasimende amasha oda kabusha kithi!

I-carbon steel Ishubhu elingunxande, Iwuhlobo lwesigcawu esiyisikwele esiyisikwele esingenalutho ipayipi lensimbi elincanyana, elaziwa nangokuthi isigaba sokugoba esiqandisini.Yenziwe ngensimbi egoqiwe eshisayo engu-Q235 eshisayo noma ebandayo egoqiwe noma ipuleti lekhoyili njengesisekelo ngokugoba okubandayo bese kuba nge-high frequency welding eyenziwe ngomumo wengxenye yesikwele nosayizi wensimbi.Ngaphezu kokuqina kodonga, ubukhulu bekhona kanye nokuqina konqenqema kweshubhu lesikwele elishisiwe eligoqiwe lifinyelela noma lidlule izinga lokumelana nokushisela abandayo okwenza ishubhu yesikwele.

I-Carbon Steel Rectangular Tubing Classification

Ishubhu lensimbi elingenamthungo kanye neshubhu lensimbi elishiselwe (ipayipi elishiselwe) elishisayo eligoqiwe eliyisikwele elingenamthungo, ishubhu lesikwele elidonswa ngokubanda elingenamthungo, ishubhu lesikwele elingenamthungo, ishubhu lesikwele elishiselwe.

Ipayipi eliyisikwele elishiselwe lihlukaniswe laba:

1, ngokwenqubo: i-arc welding square tube, ukumelana ne-welding square tube (imvamisa ephezulu, imvamisa ephansi), i-gas welding square tube, ishubhu yesikwele yokushisela isithando somlilo;

2, ngokusho kwe-weld - ipayipi le-welding ye-seam ye-square, i-spiral welding square pipe

Indlela Yokuhlonza Ishubhu elingunxande leCarbon Steel

1. Ipayipi elingunxande elingelona iqiniso neliphansi kulula ukuligoqa.Ukugoqa imigqa ehlukene ephukile eyakhiwe phezu kweshubhu elingunxande.Lesi sici sivame ukuhamba ngobude be-longitudinal bomkhiqizo.Isizathu sokugoqa ukuthi ngenxa yokuphishekela ukusebenza kahle okuphezulu kwabakhiqizi mbumbulu nabasezingeni eliphansi, inani lokucindezela likhulu, indlebe iyakhiqizwa, ukugoqa okulandelayo kuyagoqwa, umkhiqizo ogoqiwe uzoqhekeka ngemuva kokugoba, namandla insimbi iyancipha kakhulu.

2. Ukubonakala komgunyathi wepayipi elingunxande kuvame ukuba nento ephawuliwe.Ama-pockmark awavamile futhi awalingani endaweni yensimbi ebangelwa ukuguga okukhulu kwe-rolling groove.I-Groove rolling ivamise ukweqa izinga ngenxa yokuphishekela inzuzo yabakhiqizi bamapayipi angama-rectangular angenalutho.

3. Ubuso beshubhu mbumbulu nephansi elingunxande kulula ukukhiqiza izibazi.Kunezizathu ezimbili :(1).I-Fake rectangular tube material ayifani, ukungcola.(2).Abakhiqizi be-Shoddy baqondisa imishini elula, kulula ukunamathela ensimbi, lokhu kungcola

4. I-Shoddy material surface kulula ukuqhekeka, isizathu siwukuthi i-billet yayo i-adobe, i-adobe pores, i-adobe enkambisweni yokupholisa ngenxa yendima yokucindezeleka okushisayo, i-crack, ngemva kokugoqa kukhona imifantu.

5. Ipayipi elingunxande eli-Shoddy kulula ukulinwaya, isizathu siwukuthi umshini wokukhiqiza amapayipi angama-rectangular ongenalutho ulula, ukukhiqiza kalula i-burr, ukunwaya ingaphezulu lensimbi.Imihuzuko ejulile inciphisa amandla ensimbi.

6. Ishubhu elingunxande elingumgunyathi ngaphandle kokucwebezela kwensimbi, okubomvu okukhanyayo noma izizathu zamaphuzu amabili, i-billet yayo i-adobe.Izinga lokushisa eligoqayo lezinto ezingenalutho alijwayelekile, izinga lokushisa labo lensimbi likalwa ngokubonakalayo, ngakho alikwazi ukugoqwa ngokuhambisana nencazelo eshiwo. indawo ye-austenite, futhi ukusebenza kwensimbi ngokwemvelo akukwazi ukufinyelela izinga.

7. Imigoqo eguquguqukayo yamashubhu mbumbulu nangaphansi angunxande mincane futhi iphansi, ngokuvamile ebonakala igcwele ukunganeliseki.Isizathu siwukuthi umenzi unokubekezelelana okukhulu okungalungile kanye nokucindezela kwemigqa embalwa yokuqala yemikhiqizo eqediwe

8. Ingxenye yesiphambano seshubhu elingunxande elingumgunyathi liyi-oval, isizathu siwukuthi umenzi ukuze alondoloze izinto zokwakha, ukucindezela kwe-roller eqediwe phambi kokubili kukhulu, amandla ale rebar ayancipha kakhulu, kodwa futhi. ayihlangabezani nendinganiso yosayizi womumo we-rebar.

9. Ukubunjwa kwensimbi yekhwalithi ephezulu kuyiyunifomu, i-tonnage yomshini wokugcoba obandayo iphezulu, futhi ubuso bokuphela kwekhanda lokusika bushelelezi futhi buhlelekile.Ngenxa yezinto ezimbi zezinto zomgunyathi nezingaphansi, ubuso bokugcina bekhanda elisikiwe buvame ukuba nesimo senyama ewayo, okungukuthi, ukucwebezela okungalingani nokungeyona okwensimbi.Futhi ngenxa yokuthi umkhiqizo womkhiqizi usika ikhanda kancane, ikhanda nomsila kungavela indlebe enkulu.

10. I-Fake rectangular tube material iqukethe ukungcola okuningi, ukuminyana kwensimbi kuncane, futhi usayizi awubekezeleleki uma kungekho caliper ye-vernier, ingakalwa futhi ihlolwe.Isibonelo, ku-rebar 20, indinganiso kazwelonke ibeka ukuthi ukubekezelelana okungalungile okuphezulu ngu-5%.Uma ukala u-9M, isisindo sayo sethiyori sempande eyodwa singama-120kg, futhi isisindo saso esincane kufanele sibe: 120x (L-5%) = 114kg.Isisindo sangempela sempande eyodwa esilinganisiwe sincane kuno-114kg, ngakho iyinsimbi mbumbulu %.Ngokuvamile, amanani aphelele asebenza kangcono, ikakhulukazi ngenxa yamaphutha anqwabelene kanye nethiyori yamathuba.

11. I-diameter yangaphakathi yepayipi elingunxande elingenalutho liyashintshashintsha kakhulu, ngenxa yalezi zizathu ezilandelayo: Ukungaqini kwezinga lokushisa kwensimbi kunobuso be-Yin - Yang.Ukwakheka kwensimbi akulingani.Ngenxa yokuthi imishini ilula, amandla esisekelo aphansi, ukugxuma kwesigayo kukhulu.Kuzoba noshintsho olukhulu phakathi nesonto elifanayo, ukuze ukuqinisa kungafani futhi kulula ukuphuka.

12. Uphawu lokuhweba nokuphrinta kwamashubhu ekhwalithi kusezingeni.

13. Isikhala samashubhu angunxande anobubanzi obungaphezulu kuka-16 singaphezu kwe-IM.

Imigoqo yobude be-rebar yensimbi e-shoddy ivamise ukuba namagagasi.

I-Carbon Steel Rectangular Tubing Ifomula yokubala

2 [(a - d - 2 r + PI (d/r + 2) / 2 + (b - d - 2 r + PI (d/r + 2) / 2) x7.85 d (kg), a, b ngobude nobubanzi obungunxande (m), r (m) emagumbini amane omgodi weshubhu, i-arc radius eyindilinga, d yokujiya kodonga (mm).

| Into | I-MS hollow mild square erw square and rectangular Steel Pipes and Tubes |

| Okubalulekile | SPHC, Q195,Q215,Q235,Q345,SAE1010,SAE1020, API impahla ejwayelekile, ASTM A53 A,B |

| Ukujiya kodonga | 0.5-20 mm |

| ububanzi obungaphandle | I-SHS: 15*15-400*400mm, RHS: 20*25-400*300mm |

| Ubude | 2m-12m noma ngokwesidingo samakhasimende |

| Ukujiya Ukubekezelelana | + 5%- |

| Ukwelashwa Okungaphezulu | Umdwebo omnyama/indawo evanishiwe, uwoyela wokunqanda ukugqwala, uthayela |

| Ukuphela kwepayipi | Isiphetho esingenalutho |

| Ukumaka | Ngokwemfuneko yekhasimende |

| I-International Standard | I-ASTM A500, GB/T6728-2002 |

| Ukusetshenziswa | Ukumakhenikha nokukhiqiza, Isakhiwo sensimbi,Ukwakhiwa komkhumbi, ukubhulabhula, i-chassis yezimoto |

| Isitifiketi | ISO,BV,API |

| I-ODM/OEM | etholakalayo |

Ingqikithi Yendaba

| Ibanga | C | Mn | Si | S | P | I-UTS(MPa) | YS(MPa) | I-EI(%) |

| Q235B | 0.12-0.20 | 0.30-0,70 | 0.30 | 0.045 | 0.045 | 375-500 | 235 | 26 |

| Q345B | 0.12-0.20 | 1.20-1.60 | 0.20-0,55 | ≤0.045 | ≤0.045 | 510-600 | 345 | 22 |

| 20#(GB) | 0.17-0.23 | 0.38-0.65 | 0.17-0.37 | ≤0.030 | ≤0.030 | 410-550 | ≥245 | ≥20 |

Isibonisi somkhiqizo