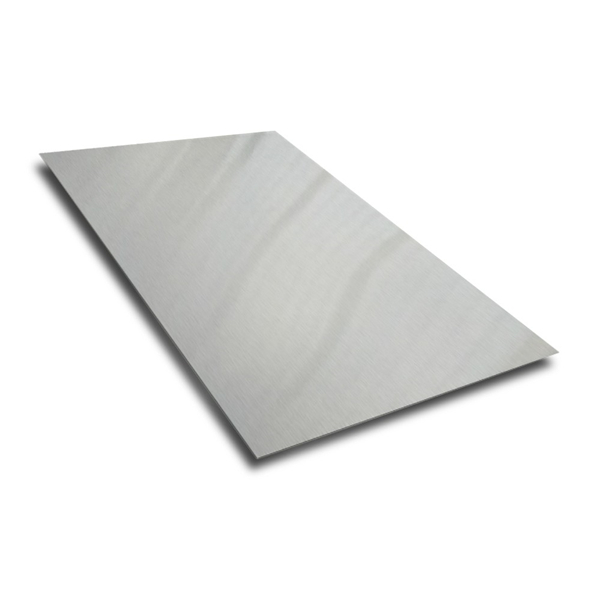

316L Ipuleti Lensimbi Engagqwali

Ipuleti lensimbi engagqwali linendawo ebushelelezi, ipulasitiki ephezulu, ukuqina, namandla emishini, futhi alikwazi ukugqwala ngama-asidi, amagesi e-alkaline, izixazululo, neminye imidiya.Iyinsimbi engagqwali kalula kodwa engagqwali.Ipuleti lensimbi engagqwali lisho ipuleti lensimbi elimelana nokugqwala ngenxa yemithombo yezindaba ebuthaka efana nomkhathi, isitimu, namanzi, kuyilapho ipuleti lensimbi elimelana ne-asidi lisho ipuleti lensimbi elimelana nokugqwala ngezinto ezithinta amakhemikhali njenge-asidi, i-alkali. , kanye nosawoti.Ipuleti lensimbi engenasici linomlando wekhulu eli-1 kusukela ekuqaleni kwekhulu lama-20.Ipuleti lensimbi engagqwali ngokuvamile igama elivamile lepuleti lensimbi engagqwali kanye nepuleti lensimbi elimelana ne-asidi.Ipuleti lensimbi engagqwali lisho ipuleti lensimbi elimelana nokugqwala ngenxa yemithombo yezindaba ebuthaka efana nomkhathi, isitimu, namanzi, kuyilapho ipuleti lensimbi elimelana ne-asidi lisho ipuleti lensimbi elimelana nokugqwala ngezinto ezithinta amakhemikhali njenge-asidi, i-alkali. , kanye nosawoti.Selokhu kwavela amapuleti ensimbi engagqwali ekuqaleni kwaleli khulu leminyaka, ukuthuthukiswa kwezingcwecwe zensimbi engagqwali kuye kwabeka isisekelo esibalulekile esibalulekile sokuthuthukiswa kwezimboni zesimanje kanye nenqubekelaphambili yesayensi nezobuchwepheshe.

I-Stainless Steel Plate, Inqubo Yokukhiqiza

Ukulungiswa kwensimbi → ukushisisa → ukubhoboza okushisayo → ukusika ikhanda → ukucosha → ukucwenga → ukugcoba → inqubo yokugoqa ebandayo → ukugcoba → ukwelashwa kokushisa kwesixazululo → ukuqondisa → ukusika ipayipi → ukukha → ukuhlolwa komkhiqizo oqediwe.

I-Stainless Steel Seamless Square Tubing, Ukuhlaziywa kokusebenza

Insimbi ingasabela nge-oxygen emkhathini ukuze yakhe ifilimu ye-oxide phezulu.I-iron oxide eyakhiwe ku-carbon steel evamile izoqhubeka ne-oxidize, ikhulise ukugqwala futhi ekugcineni yenze izimbobo.Lokhu kungenziwa kusetshenziswa upende noma ucwecwe lwensimbi olumelana ne-oxidation ukuze kuvikelwe ingaphezulu le-carbon steel, kodwa lokhu kunamathela kuyifilimu encane kuphela.Uma ukugqoka konakalisiwe, insimbi engaphansi iqala ukugqwala futhi.Ukuthi ishubhu lensimbi engagqwali ligqwalile yini kuhlobene nokuqukethwe kwe-chromium kunsimbi.Lapho okuqukethwe kwe-chromium ensimbi kufinyelela ku-12%, ingaphezulu leshubhu lensimbi engagqwali likhiqiza ungqimba lwe-passivation kanye ne-chromium eminyene ecebile oksidi ukuze kuvikelwe indawo engaphezulu futhi kuvimbele ukuphinda kufakwe kabusha.Lolu ungqimba lwe-oxide luncane kakhulu, lapho kubonakala khona ukukhanya kwemvelo kwendawo yensimbi, kunikeza insimbi engagqwali indawo eyingqayizivele.Uma ifilimu ye-chromium ilimele kanye, i-chromium esensimbi nomoya-mpilo osemkhathini ukuze kuvuselelwe ifilimu ye-passivation, qhubeka nokudlala indima yokuvikela.Kwezinye izindawo ezikhethekile, insimbi engagqwali nayo izovela okunye ukugqwala nokwehluleka kwendawo, kodwa insimbi engagqwali ne-carbon steel kuhlukile, ngeke kubonakale ukugqwala okufanayo nokwehluleka, ngakho-ke imvume yokugqwala yeshubhu lensimbi engenasici ayinangqondo.

Imininingwane

| Igama Lomkhiqizo | I-Stainless Steel Plate | |

| Ibanga lensimbi | 300 uchungechunge | |

| Okujwayelekile | ASTM A213, A312, ASTM A269, ASTM A778, ASTM A789, DIN 17456, DIN17457, DIN 17459, JIS G3459, JIS G3463, GOST9941, EN10216, BS3629, GB | |

| Okubalulekile | 304, 304L, 309S, 310S, 316, 316Ti, 317, 317L, 321, 347, 347H, 304N, 3 16L, 316N, 201, 202 | |

| Ubuso | Ukupholisha, ukuthungatha, ukukha, okukhanyayo | |

| Uhlobo | hot rolling futhi kubanda rolling | |

| Imigomo yohwebo | Imigomo yentengo | FOB, CIF, CFR, CNF, Ex-work |

| Imigomo yokukhokha | T/T, L/C, westen union | |

| Isikhathi sokuthumela | Ukulethwa okusheshayo noma njengenani le-oda. | |

| Thumela ku | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Italy, India, Egypt, Oman, Malaysia, Kuwait, Canada, Viet Nam, Peru, Mexico, Dubai, Russia, njll | |

| Iphakheji | Iphakheji elijwayelekile lokuthekelisa elifanele ukuhamba olwandle, noma njengoba kudingeka. | |

| Isicelo | Isetshenziswa ekuhlobiseni, inhle futhi ihlala isikhathi eside.Izitsha zokuhlala, amabhodwe, izinkezo, amabhodwe, izitsha, imimese yetafula, njll. zonke zenziwe ngensimbi engagqwali. | |

| Oxhumana naye | Uma unemibuzo, sicela ukhululeke ukuxhumana nami. | |

Ukwakheka Kwamakhemikhali

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7.5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0.22 | 0. 24 -0 .26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

Isibonisi somkhiqizo